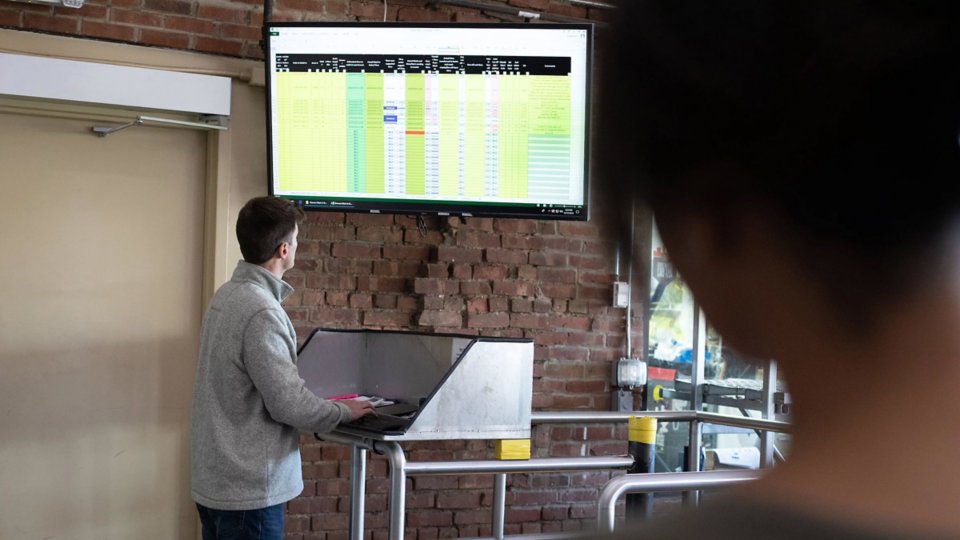

FactoryTalk® View Site Edition (SE) is a scalable and versatile HMI/SCADA solution designed to meet the needs of modern industrial environments. Whether you're managing a single operator station or a complex, distributed system, FactoryTalk View SE delivers a consistent, real-time view of your operations.

Built with flexibility in mind, it supports a wide range of architectures and client options - including mobile and web access, while offering seamless integration with our broader ecosystem. From engineering and maintenance to operations and enterprise IT, FactoryTalk View SE empowers every stakeholder with the tools and insights needed to drive productivity and informed decision-making.