Miles of new pipelines are built each year to help meet rising demands for transporting oil, gas, and petroleum products. Whether your pipelines are remote and unmanned or pass near city centers, the ability to keep product safely flowing 24/7 is critical.

Solutions for Hydrocarbon Pipeline Automation

Modernize your operations and take advantage of connected technologies to address maintenance, reliability, and safety challenges in your operations.

Rockwell Automation and our PartnerNetwork™ members bring expertise in new pipeline construction and experience with existing system upgrades. There’s no reason to work through these challenges alone. We’re here to help. Work with a trusted partner who can provide the right technology, solutions, services, and expertise to keep your pipelines flowing safely.

Explore Operational Excellence in Pipelines

Achieving operational excellence in oil and gas midstream operations involves electrification, remote monitoring, and digital capabilities. Electrifying processes reduces carbon footprints and boosts efficiency. Remote monitoring enables real-time data collection for proactive maintenance and minimized downtime. Digital tools like advanced analytics and machine learning provide actionable insights, optimizing performance

and safety.

Efficient and Safe Pipeline Operations

Sensia-delivered Solutions

Sensia, a JV created by Rockwell Automation and Schlumberger in October 2019, has a team of knowledgeable engineers and project managers who understand your issues. By taking advantage of easy to use tools and modern technology, Sensia has helped global customers design solutions that help keep your pipeline operations at optimized performance.

Sensia also provides various engineering services that can help you reduce risk while helping keep projects on time and on budget.

Sensia’s integrated information, control, and power solutions for pipeline management are suitable for:

- Pipeline safety systems

- Pump and compressor control

- Condition monitoring

- SCADA systems

- Terminal automation systems

- Metering and LACT unit control solutions

- Blending and sampling solutions

- Storage management solutions

Pipeline Operations Optimization

You are under pressure to increase efficiency, enhance public safety, protect workers, and deliver higher returns for shareholders. Smart technologies, including Industrial IoT devices, cloud computing, and intelligent gas pipeline software, hold tremendous promise to help meet those demands.

Smart Technologies Can Help Cut Costs, Ease Compliance, and Enhance Safety

There are many options for smart devices, and many ideas of how to leverage IoT technology. It can be difficult to know where to begin. We have found five key areas of project focus that can make a significant difference in achieving success with smart technologies:

- Quality data

- Energy optimization

- Root-cause analysis

- Predictive monitoring

- Condition-based maintenance

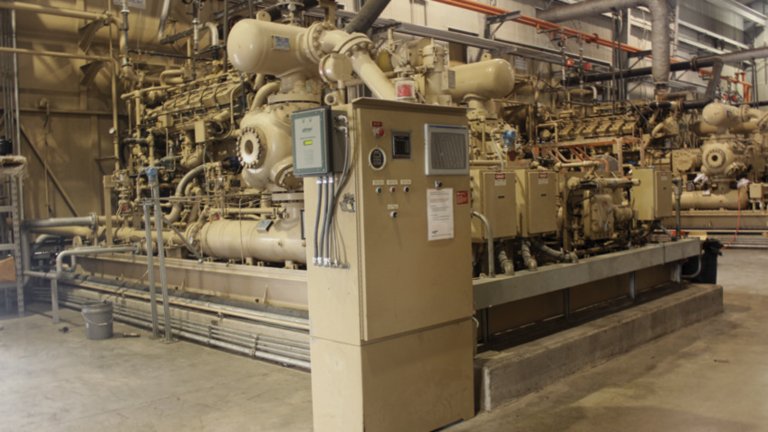

Compressor and Pump Station Control

Controls and Analytics for Reliable, Safe, Energy Efficient Pumping

Our pipeline solutions can help you improve uptime, safety, and energy consumption.

Products and Capabilities

Achieve Operational Excellence with a Wide Portfolio of Solutions

Our integrated systems allow operators to visualize information anywhere in the organization for fast decision-making. By using disruptive technologies, we are able to offer a fully digitized pipeline experience. Our solutions help you obtain actionable data accessible from various devices. This technology drives safer and more efficient operations with secure remote access.

What is Pipeline Transportation?

Pipeline transportation is a widely used method for moving fluids like crude oil, natural gas, and refined products over long distances through underground or above-ground pipes. While it is efficient and cost-effective, the process comes with several challenges, including the risk of leaks or ruptures, pressure imbalances, equipment failures, and difficulties in monitoring vast pipeline networks in real-time. These issues can lead to environmental damage, safety hazards, and costly downtime if not promptly addressed. To overcome these challenges, many operators are turning to pipeline automation—an advanced solution that uses sensors, control systems, and real-time data analytics to monitor, regulate, and optimize pipeline operations.

What is Pipeline Automation?

Pipeline automation in the energy sector refers to the use of advanced control systems, sensors, and software to monitor and manage the flow of oil and gas or other energy resources through pipelines. This technology enables real-time data collection, leak detection, pressure and flow regulation, and remote operation of valves and pumps, helping to improve safety, reliability, and efficiency. By automating key processes, energy companies can minimize human error, respond quickly to anomalies, reduce operations costs, and ensure compliance with environmental and safety standards.

How Does Oil and Gas Pipeline Automation Work?

Energy pipeline automation works by integrating sensors, programmable logic controllers (PLCs), and supervisory control and data acquisition (SCADA) systems to continuously monitor and control pipeline operations. Sensors placed along the pipeline collect data on pressure, temperature, flow rate, and potential leaks, which is then transmitted to a central control center via communication networks.

The SCADA system processes this data in real-time, enabling operators to make informed decisions or allowing the system to automatically adjust valves, pumps, and compressors as needed. This closed-loop control ensures optimal performance, rapid response to issues, and seamless coordination across the entire pipeline network.

Benefits of Oil and Gas Pipeline Automation

Oil and gas pipeline automation delivers numerous advantages that improve safety, efficiency, and overall operational effectiveness. Key benefits include:

- Real-time monitoring and control: Enables immediate detection and response to issues such as leaks, pressure changes, or equipment malfunctions.

- Improved safety: Reduces the risk of accidents and environmental damage by identifying and addressing problems quickly.

- Enhanced efficiency: Optimizes flow rates, pressure, and resource allocation for more reliable and cost-effective energy transport.

- Remote operation: Minimizes the need for on-site personnel, reducing labor costs and exposure to hazardous environments.

- Regulatory compliance: Automatically records operational data to support reporting and audits, helping meet safety and environmental standards.

Recommended for You

Others also viewed

Based on your activity