The electric automotive industry is at a turning point. Bloomberg estimates that by 2040, 54% of new vehicle sales will be electric. And by 2030, we’re looking at 100% of passenger vehicles in China and India being electric.

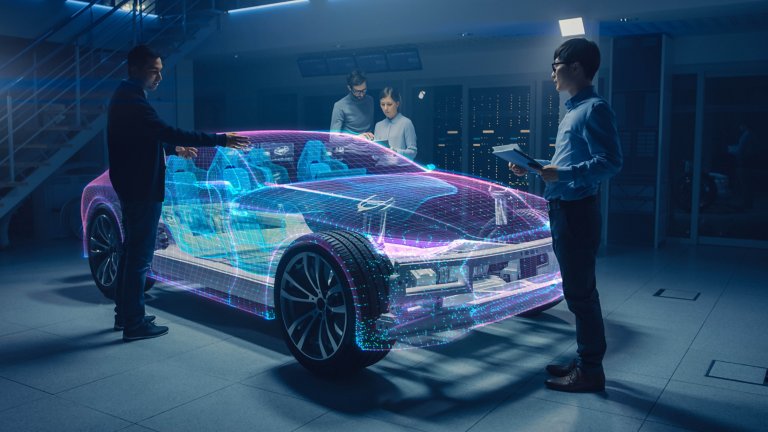

A whole new approach is needed and fast for brand owners and suppliers. Electric vehicle manufacturers must shift processes and technology to serve these changing market needs. We can help accelerate your electric vehicle production to compete better with smart, flexible operations and integrated automation solutions.