Automation Fair is a registered trademark of Rockwell Automation.

Off-site Tours offer an exclusive inside-access experience to see technology and solutions on the leading edge of manufacturing. Complement your training and networking with inspiration to create your next chapter.

ATS Life Science Systems: High-tech Automation for MedTech Innovation

Take a walk through ATS Life Sciences Systems’ state-of-the-art operations to discover how they help global life sciences leaders get life-changing products to market faster. Hear how ATS designed their process for maximized productivity and speed, building engineered-to-order, high-speed, high-precision assembly machines to meet surging demand for advancements like self-administered autoinjectors. Standardized on Rockwell Automation technology, you’ll see how ATS machines are built for ease of use and drive quality and yield with the latest in assembly automation.

Shaping the Future of Manufacturing at the Connected Systems Institute

How do you keep up with fast-paced innovation, a changing workforce and dynamic market? This tour of the Connected Systems Institute (CSI) at the University of Wisconsin-Milwaukee unveils ways to simplify the complexity. Explore the Manufacturing Test Bed, used for concept testing and planning by leading manufacturers, where students gain valuable hands-on experiential learning with industry partners. Experience the brand-new Microsoft AI Co-Innovation Lab, the Digital Twin Lab and digital transformation research space. The AI Co-Innovation Lab helps catalyze businesses toward AI adoption and acceleration through hands-on collaboration. CSI tours will be offered in conjunction with the Rockwell Headquarters Experience.

Goose Island Brewery: Where Technology Meets Taste

Take a private tour of Chicago’s original craft brewery. Since 1988, Goose Island Beer Co. has been brewing in Illinois with industry-leading technology. Hear how their culture of quality, process and packaging automation has enabled Goose Island to successfully scale from local brewer to international brand. You’ll explore the production brewery and follow the brewing process that relies on Rockwell Automation to get the most barrels out of every batch and achieve world-class packaging OEE.

Experience the Power of Process Automation at the PTU

Step into the role of a plant operator and see the future of plant operations in action at the PTU® (Process Training Unit), powered by Endress+Hauser instrumentation and seamlessly integrated with the Rockwell Automation PlantPAx® system. Dive into the inner workings of a plant and interact with a full suite of the latest instrumentation, advanced controls, integrated intelligent motor control center and sophisticated analytics and diagnostics. The PTU at George E. Booth Co. was built with access to data in mind, immersing you in the types of operations, diagnostics and troubleshooting found in real-life process plants.

Fulfillment Futurized at Proctor & Gamble

Witness automated warehouse fulfillment in action at Proctor & Gamble, a world leader in consumer products and makers of iconic brands like Pampers and Tide. At the Greater Chicago Fulfillment Center, you’ll see a fleet of robotic innovation and advanced material handling enabled by the latest industrial operations technology, getting product to shelves near you with precision, accuracy and speed. Explore unique automated layer picking, high-speed case picking and high-density storage applications while sharing feedback and your own best practices with peers from around the world.

Industry & Academia Come Together at Purdue University Northwest

Home of the first US ABET-accredited Mechatronics Engineering Technology degree program, Purdue University Northwest College of Technology’s cutting-edge facilities and hands-on experiences are preparing the workforce of tomorrow. See the Commercialization and Manufacturing Excellence Center that brings industry and academia together. Dive into how Purdue Northwest is advancing applied research and collaborating with key industry partners at the Center for Innovation through Visualization & Simulation. Get insights from their state-of-the-art labs with advanced manufacturing-training equipment including robots, PLCs, electrical and mechanical machinery.

Your VIP Ticket Inside Rockwell Automation Headquarters

Spend the day in Milwaukee touring production lines, labs and demo experiences at Rockwell Automation’s headquarters in the historic Allen Bradley building. See digital transformation in action at the 100-C Contactor Production Line showcasing cutting-edge technology and featuring our PartnerNetwork® ecosystem. Explore where innovation begins at state-of-the-art lab facilities. Get behind-the-scenes insights from our Customer Experience Centers full of interactive demos on sustainability, flexible manufacturing, Ethernet/IP In-cabinet Solutions and cybersecurity. Cap it off with a sneak peek at the new OTTO Autonomous Mobile Robot production line in development.

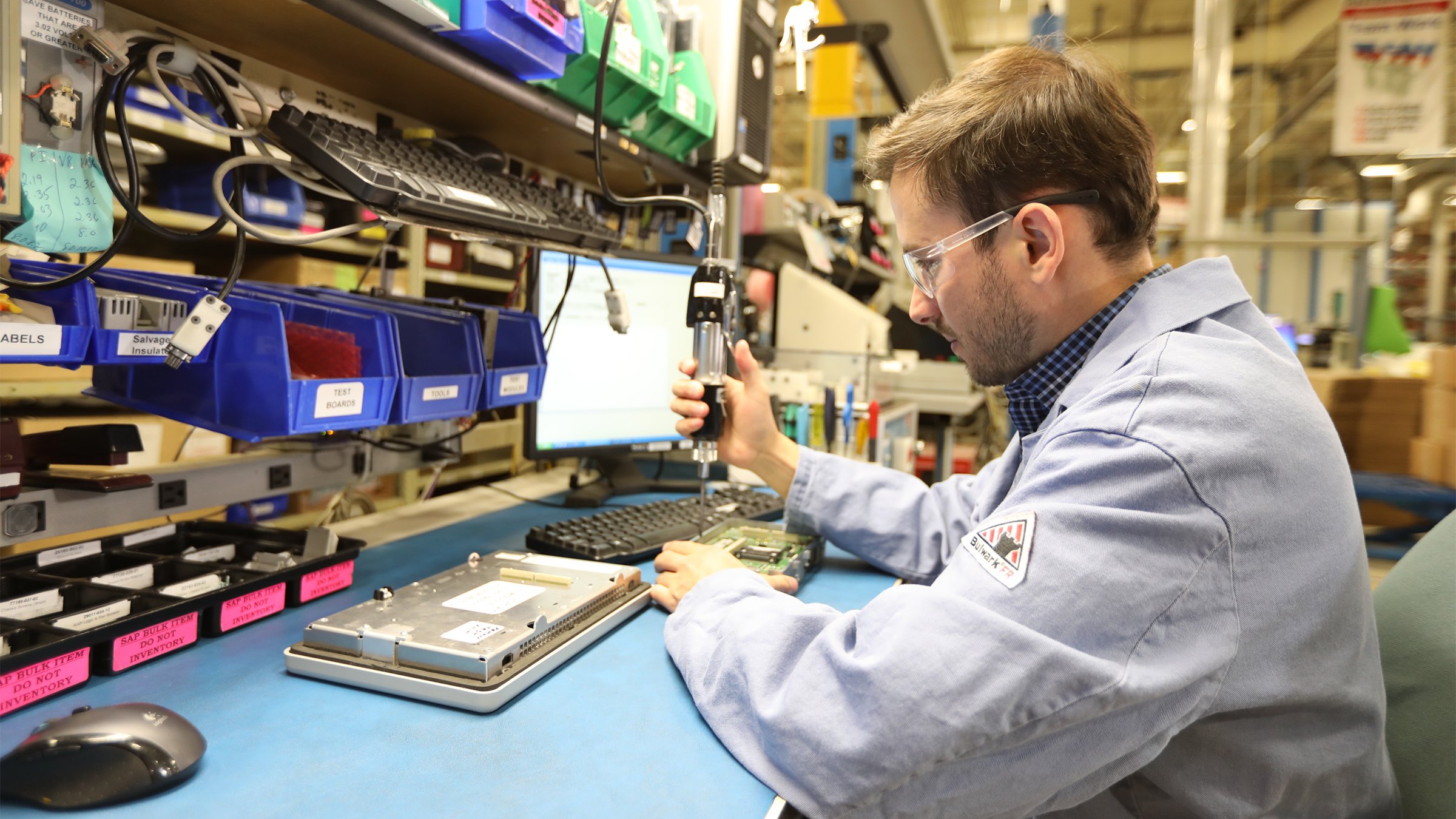

Restored & Ready Equipment: The Rockwell Automation Remanufacturing & Repair Center

Experience remanufacturing like you’ve never seen it before. Tour Rockwell Automation’s Remanufacturing & Repair Center for a firsthand look at the industry’s preeminent reman house for Allen-Bradley® products and thousands of third-party brands. See smart testing equipment and advanced diagnostics in action for component-level repair and in-house product certification that takes cybersecurity and safety into account. You’ll learn about the early days of machine control and how legacy equipment is made new to help protect your investment and integrate with modern technology and data.

Automation Fair is a registered trademark of Rockwell Automation.