Founded in 1989, TEC Engineering is a leader in automated bulk handling solutions for the plastics and packaging industries. The Mexico-based firm has equipment installed in more than 700 client facilities around the world.

- Streamline material handling

- More efficiently use floor space, equipment, and production line

- Reduce manual labor

- Automated multiplexing material handling solution

- CompactLogix™ 5380 Programmable Controllers

- PowerFlex® 525 AC Drives

- Studio 5000 Logix Designer® application

- Increased line efficiency and accuracy

- Reduced equipment needs and costs

- Reduced installation time

- 80% potential labor savings

- Estimated 18-month ROI

Maura Minardi is CEO of TEC Engineering, a leader in automated bulk handling solutions for the plastics and packaging industries. Founded in 1989, TEC has equipment installed in more than 700 client facilities around the world. The Mexico-based firm is a gold-level member of the Rockwell Automation PartnerNetwork™ program.

“We’re focused on increasing our client’s throughput and efficiency with innovative, highly automated solutions,” Minardi says. “This includes our new multiplexing application, which optimizes material transport by allowing customers to use a single master conveying line for material transport.”

Challenge

Improve Material Handling Processes While Reducing Costs

Traditionally, materials are delivered from the warehouse to dedicated conveying lines that then feed materials to a production line. With the average facility having several production lines, each line must be ‘fed’ separately.

“Our clients were interested in a solution that not only streamlined the process but also reduced forklift movement and human handling,” Minardi explains.

Solution

Rethinking Material Transport

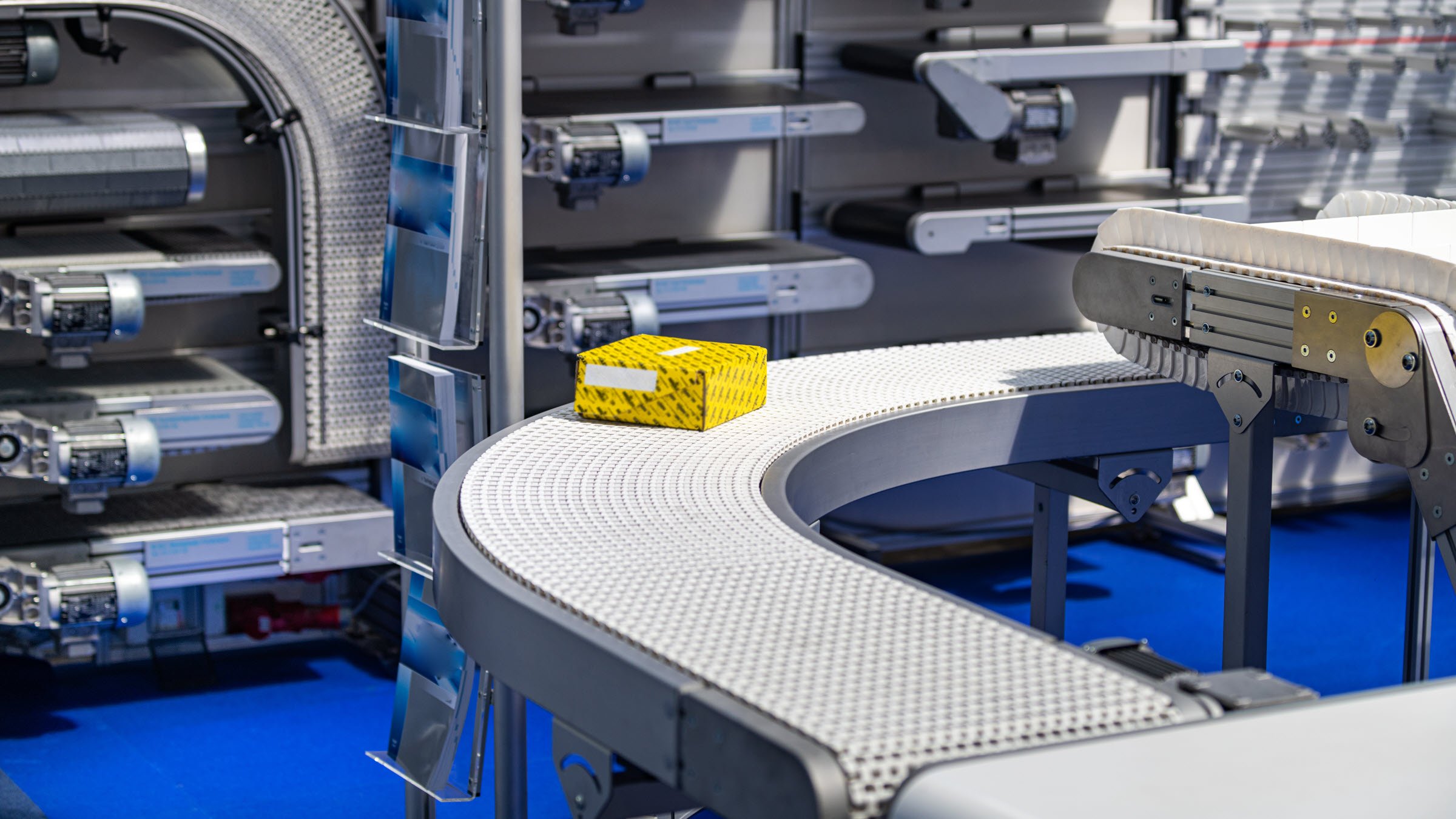

TEC’s multiplex solution differs from traditional conveying offerings because it uses only one trunk line conveyor to transport materials to multiple production lines.

“It’s ideal for large packaging and plastics manufacturing clients with various formats, products and production lines,” Minardi says.

The multiplexing solution uses several Rockwell Automation products, including CompactLogix™ 5380 Programmable Controllers; PowerFlex® 525 AC Drives, and Studio 5000 Logix Designer® application.

“Rockwell Automation has been involved in all of our research and product development for multiplexing,” Minardi explained. “Their technologies are user-friendly, drive system connectivity and communication, and provide scalability for line expansion.”

Result

Labor and Operations Savings; Line Efficiency

Because only one master conveyor is needed, TEC’s multiplex operation reduces the amount of equipment and floorspace needed.

“That means reduced installation time and reduced operation and maintenance costs,” Minardi said. “The system also improves line efficiency and reduces downtime with automatic notifications that determine how much material each line needs to receive.”

Several large multinational packaging companies report that after implementing the TEC multiplex solution, they reduced labor for staging, production and forklift operations by as much as 80%. TEC estimates that’s about a $500,000 annual savings per facility and that the multiplex solution’s average return on investment is 18 months.

Published February 5, 2024