- Provides machinery protection and condition monitoring of rotating and reciprocating assets

- Offers Distributed I/O on Ethernet/IP saving installation time and wiring

- Offers easy integration and setup in Studio 5000 Logix Designer®

- Rugged, conformally coated and approved for electrical safety and hazardous areas

- Offers expansion modules for additional capabilities

- Leveraging the Rockwell Automation Integrated Architecture and its components such as controllers, HMIs, IO, sensors, etc., users will experience an enhanced level of integration, functionality and performance

- Product Selection

- Overview

- Documentation

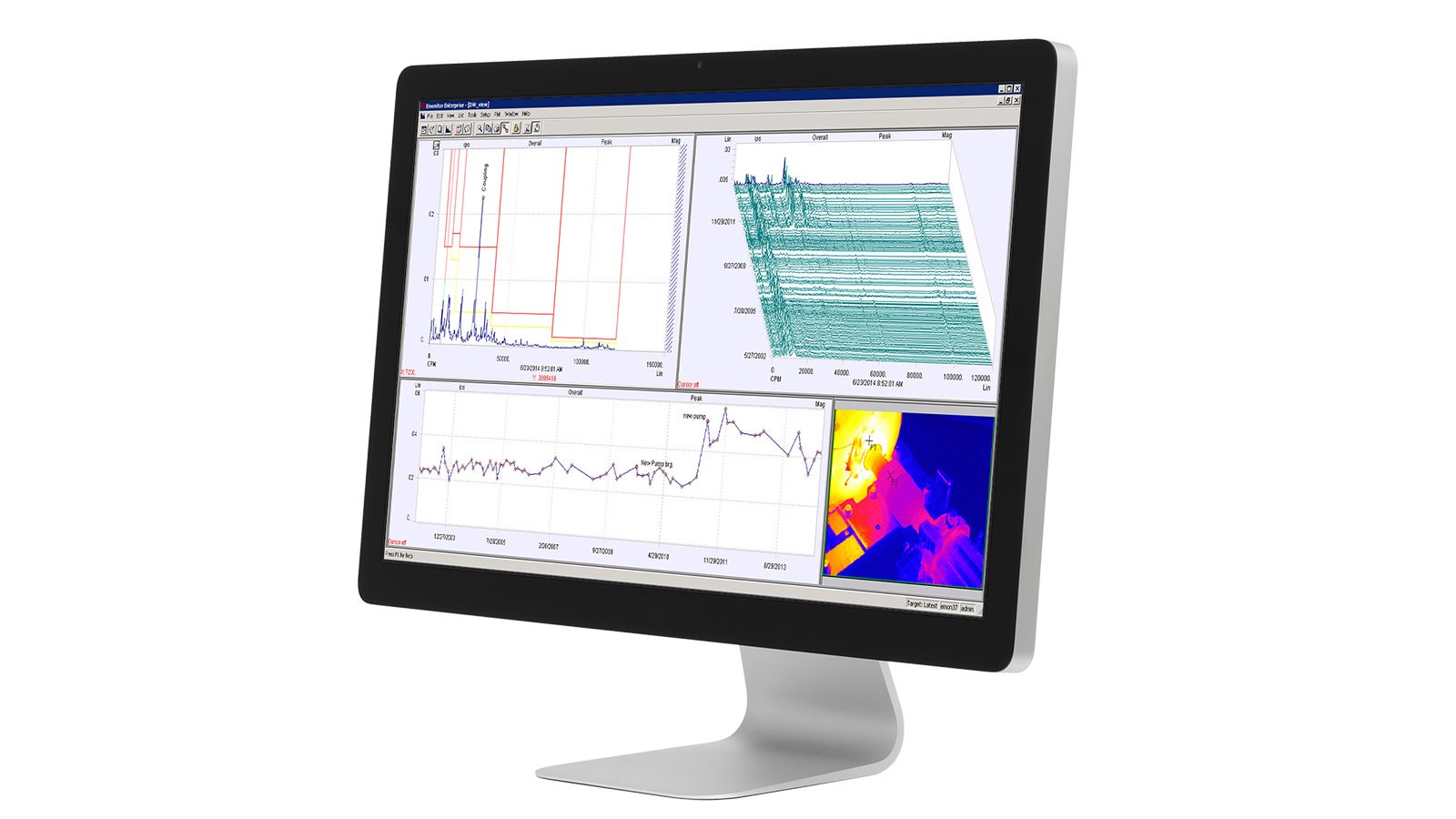

Emonitor Condition Monitoring Software

Our Bulletin 9309 Emonitor® Condition Monitoring Software works with our monitors and portable data collectors to help establish and execute a condition-based predictive maintenance program. Emonitor software provides you with a comprehensive suite of tools for long-term trending, plotting and alarming capabilities to detect the earliest possible indicators of developing machine faults.

Check out the Emonitor Learning Video series to get the most from your Emonitor software.

- ATEX

- CE Marked

- CSA Certified

- C-Tick

- UL Listed

Hazardous Area Certifications — IECex Conformity; ATEX Zone 2; UL Class 1 Div 2; Groups A, B, C, D; Country and Regional Approvals: C-Tick, Korea, Russia

Marine Certifications — American Bureau of Shipping, Bureau Veritas, De Norske Veritas, Germanischer Lloyd, Korean Register of Shipping, Registro Italiano Navale, Lloyd’s Register

Certifications apply when product is marked. See our Product Certification site for Declarations of Conformity, certificates and other certification details.

You may also be interested in

| Product Profiles | Publication |

|---|---|

| Dynamix 1444 Series Integrated Machinery Monitoring System Product Profile | 1444-PP001_-EN-P |